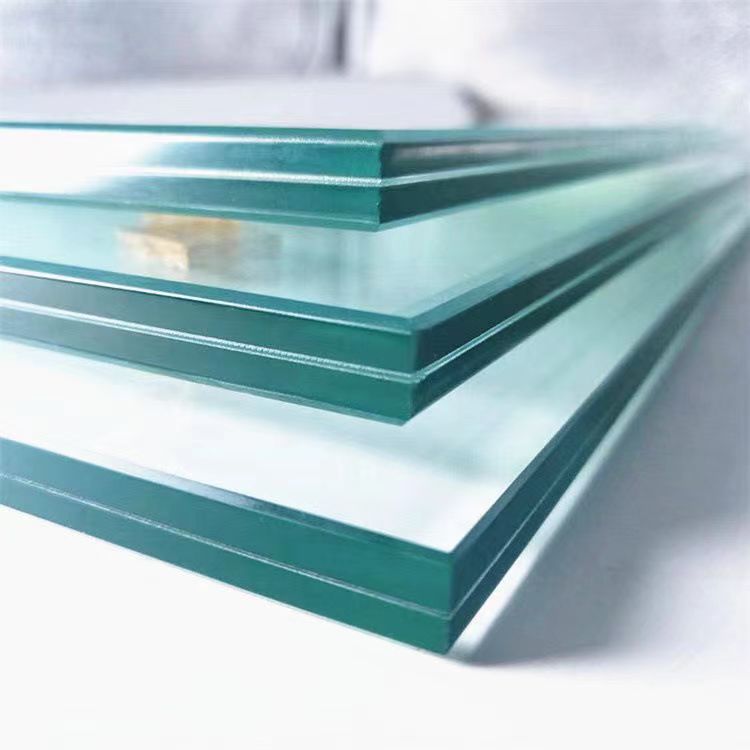

Glass has good transmittance and light transmission properties, high chemical stability, and can obtain strong mechanical strength and thermal insulation effects according to different processing methods. It can even make the glass change color independently and isolate excessive light. Therefore, Commonly used in various industries to meet different needs. Next, please read what pvb means in laminated glass and what are the characteristics of pvb laminated glass to enhance your understanding.

1. What is the difference between PVB and EVA in laminated glass?

Laminated glass is divided into pvb and eva laminated glass.

PVB lamination requires a series of equipment such as autoclaves, roller presses, and film washers. The capital investment cost is relatively high. A smaller autoclave costs RMB 400,000 to RMB 50,000. The autoclave mainly includes cleaning, laminating, pre-pressing, and Cauldron four steps.

Principle: Not much to say about cleaning and joining. The pre-pressure is to compress the air between the two pieces of glass and the middle PVB into small bubbles through a roller press, so that the two pieces of glass are adhered together through the PVB; entering the kettle is under high pressure The bubbles are compressed in the kettle until they are invisible to the naked eye through more than ten atmospheric pressures. It is characterized by relatively high strength. It is mainly used for automobile front windshields, etc.

EVA lamination only requires a lamination furnace, which mainly includes cleaning, lamination, and furnace feeding.

The principle is to pre-extract the air between the two pieces of glass through a vacuum pump to form a vacuum state in the silicone bag, and then enter the furnace to melt the EVA film at high temperature to bond the two pieces of glass together. It is characterized by bonding EVA film has relatively good strength and good light transmittance. The characteristic of EVA film is that the investment cost is relatively low, and the equipment is about more than 100,000. It is mainly used in architectural glass, such as curtain walls, lighting roofs, awnings and other interlayers.

2. What are the characteristics of PVB laminated glass interlayer film?

1. PVB is the abbreviation of Polyvinyl butyral; EVA is the abbreviation of ethylene-vinyl acetate copolymer.

2. Processing and storage conditions: PVB needs to be processed and stored under low temperature (18-22°C) and dry (humidity 25%-40%) conditions, especially the requirements for humidity are very strict, and high temperature (120-120°C) is required for lamination. 140℃) high pressure (1.0-1.5MPa), mostly produced in autoclaves; the processing and storage conditions of EVA are relatively low, the temperature does not exceed 30℃, the humidity is less than 80%, and the equipment requirements for lamination are also low. Vacuum degree ≥700mmHg (0.092Mpa), temperature 100-110℃; PVB lamination process is more complicated than EVA, takes longer and consumes more energy

3. Characteristics: The aging resistance of PVB is stronger than that of EVA, and the impact resistance of PVB is also stronger than that of EVA.

4. Usage: PVB is mostly used outdoors, such as building curtain walls, car front windshields, etc., while EVA is mostly used for interior decoration.

YAOTAI is a professional glass manufacturer and glass solution provider include range of tempered glass,laminated glass, reflective glass,float glass,mirror,Door and window glass, furniture glass, embossed glass, coated glass,textured glass and etched glass. With more 20 years development,there are two produce lines of pattern glass,two lines of float glass and one line of restoration glass. our products 80% ship to overseas,All our glass products are strict quality control and carefully packed in strong wooden case,ensure you receive the finest quality glass safety in time.

Post time: Oct-30-2023