The first glass edge grinding target

1. Glass edge grinding, can grind off the sharp edges and corners generated during cutting, to prevent injury during use.

2. Small cracks and micro-cracks are formed at the edge of the glass due to cutting, so as to eliminate local stress concentration and increase the strength of the glass.

3. When the glass has been edged, the glass geometry and size tolerance meet the requirements of glass.

4. Carry out different grades of quality processing on the glass edge, namely rough edge grinding, fine edge grinding and polishing.

5. Glass assembly needs.

Summary: Use safety, product safety, product appearance grade needs.

Second glass grinding edge suitable for processing size

1. The minimum machining width is 50mm.

2. The maximum machining width is 6000mm.

The above data are determined by the current domestic equipment.

The third classification of glass grinding edge

Classification according to glass geometry

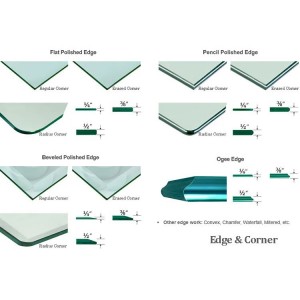

1. A straight edge (also called a T-shaped edge) is flat

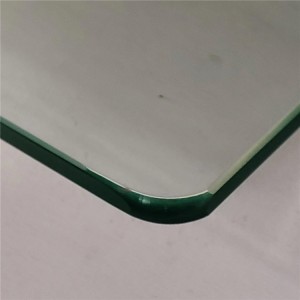

2. Round edge (also called C shape edge,pencil edge) (also called C shape edge)

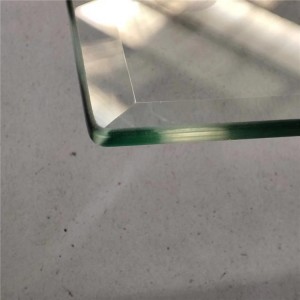

3. Bevel edge

4. Ogee edge

Classification according to processing technology

Classification according to processing technology

1. Seamed Edge

2. a. Chamfering target

Handling safety needs

Reduce the need for tempering self-explosion

b. Glass chamfering process

Is determined by grinding , under normal circumstances chamfering width is 1 or 2 mm, Angle and Angle of glass surface in 45 º.

3. Rough Ground Edge (European standard name) white spots can be seen on the edge.

Rough grinding round edge rough grinding straight edge

4. Smooth Ground Edge (European standard name) no white spots on the edge.

Fine grinding round edge fine grinding straight edge

5. Polished Edge (European standard name), polishing is processed on the basis of fine grinding, the factory rough grinding edge is not estimated to be polished.

Polish round edges Polish straight edges

1)Rough and fine edging of glass

Glass fine grinding edge: fine grinding edge is also called fine grinding edge, generally is the use of large and medium-sized glass edge grinding machine to complete, through different wheel sets for gradual fine grinding edge, according to different requirements, the use of different mesh grinding wheel. Fine grinding edge in the diamond wheel after rough grinding followed by polishing wheel polishing treatment, polished glass edge into transparent, high brightness, for the glass bar or exposed to the outside of the glass edge must use fine grinding edge. Fine grinding edge is polished after rough grinding, which is relatively expensive in terms of processing cost and slow processing speed. Sometimes, in order to ensure the polishing effect, it is necessary to grind edge twice.

Glass rough edge grinding: rough edge grinding is only using 1-3 diamond wheel for edge grinding, chamfering, edge allowed to have uneven grinding phenomenon; Generally speaking, rough grinding edge is manual grinding.

Post time: Feb-27-2023