Clock surface glass,Clock or watch glasses,Watch crystal

The company’s operation is full of characteristics, mainly engaged in glass finishing, and can provide special-shaped cutting, physical tempering, water jet cutting, ink printing, glass drilling, hot bending, sandblasting, fine grinding and polishing and other processes. The main industries involved are lamps, household appliances, instruments and meters, etc. The main business is processing electronic float glass, optical glass, instrument glass, silk screen tempered glass, photo frame glass, home appliance glass and so on. The processing thickness ranges from 0.1 to 22mm, and is widely used in various industries.

The company aims to create a domestic advanced glass deep-processing enterprise; takes “integrity, innovation, harmony” as its purpose; follows the concept of “development, win-win”, and its quality is steadily improving. It has won the favor of a large number of customers in China, and has also been sold to North America, the European Union, South America, South Korea, Japan and other markets, creating a good reputation in the industry. At present, the company is in a period of rapid development, and we look forward to cooperating with our customers to create a better future together!

Processing and customization of various specifications: home appliance glass, lamp glass, small furniture glass tempering, glass circle, instrument glass, flashlight glass, sight glass glass, oil mirror glass, water meter glass, buried lamp glass , Camera glass sheet, square glass sheet, glass mirror disc. Glass thickness: 0.8, 1.1, 1.2mm, 1.5mm, 1.8mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm.

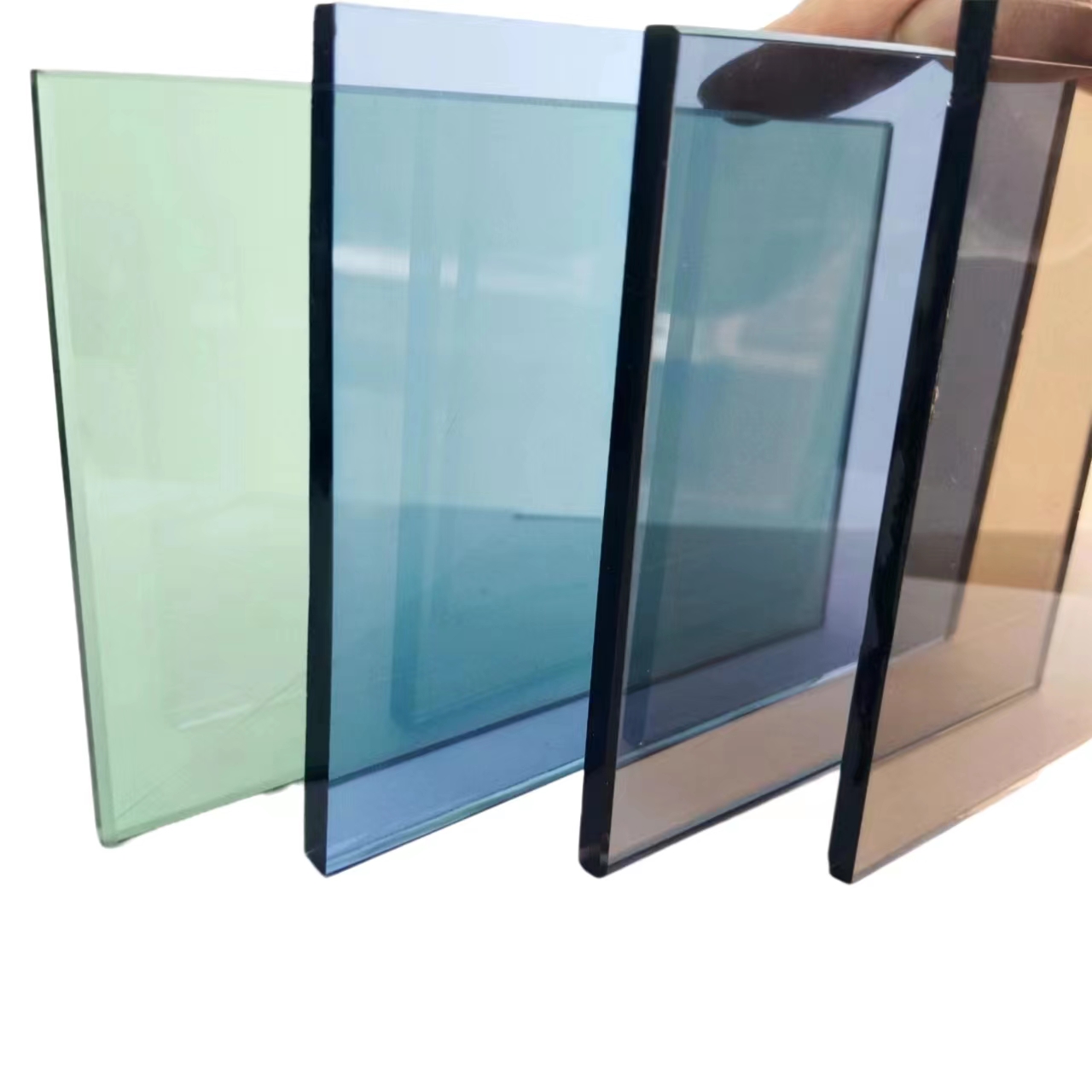

Glass varieties include: ordinary glass, ultra-clear glass, colored glass, glass mirror, etc.Available process: cutting, edging, CNC edging, water cutting, tempering, coating, silk screen, electroplating, engraving, polishing, drilling, etc. Process Description:

Ordinary cutting: use high-grade electronic grade glass as the raw material, cut into slices, place the slices on the shelf, and grind the edges (edges include smooth edges, fog edges, straight edges, round edges, chamfered edges, small beveled edges, large hypotenuse, etc.);

Then chamfer (the corner part is divided into big R angle, small R angle, cut corner, special-shaped corner, etc., mainly processed according to CAD drawings);

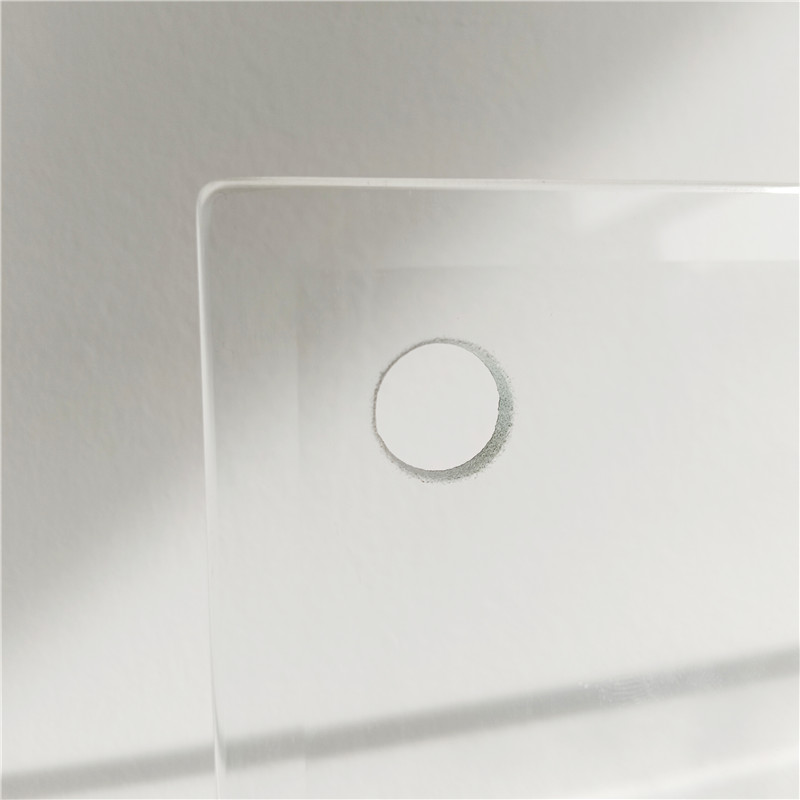

Drilling (holes are divided into square holes, round holes, various special-shaped holes, punching holes, etc.);

Surface treatment: sanding is required for the matte surface; pickling, through the pickling process, can also make the glass surface foggy;

Coating treatment: no fingerprints, anti-reflection, ITO conductive, etc.

Water cutting: need to open a very precise hole, you need not cut the hole;

Jingdiao: The hole after water cutting is relatively rough, and needs to be processed carefully and smooth, so it needs to be carved. The speed of this process is very slow, and the processing cost is relatively high;

Cleaning: The cleaning process must be carried out in every production link before the next process operation can be carried out to ensure the surface cleanliness;

Tempering: It is the process of strengthening the glass surface that everyone calls;

Silk screen printing, which some customers refer to as coloring, printing, printing, etc., can print LOGO, function keys and some patterns on the product.

Uses: Applicable Scope: Applicable to instruments and lamps, mainly for protection and decoration

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

Top