Clear Float Glass, Transparent float glass

Product Description

Clear float glass is made from molten glass which flows through the tweel to a tin bath and then to a lehr. While floating on the molten tin, gravity and surface tension cause the glass to become smooth and flat on both sides.For float glass, due to the thickness uniformity is good, the transparency of its products is also strong, because after tin surface treatment, smooth, under the action of surface tension, formed a surface is neat, flatness is good, optical performance is strong glass, the decorative characteristics of this float glass is particularly good, More with good transparency, brightness, purity, and bright indoor light characteristics, broad field of vision performance, but also with building doors and Windows, natural lighting materials of the best choice, is one of the most highly applied building materials, it can be said that in a variety of building glass, this kind of float glass is the largest application, It is one of the most important original pieces for deep processing of glass. Clear float glass with the best clarity of transparency as the main feature.

Ordinary flat glass and float glass are flat glass. Only the production process, quality is different.

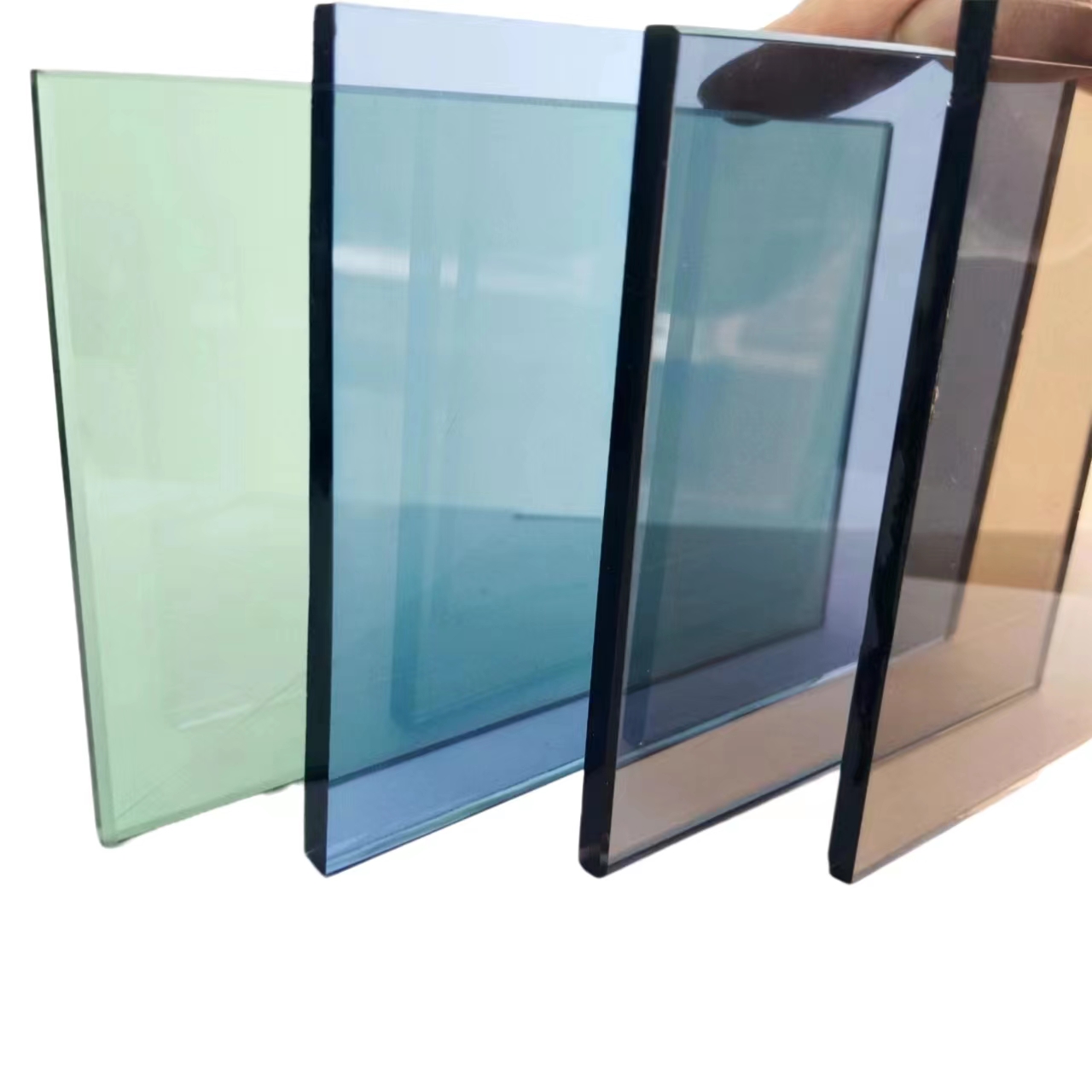

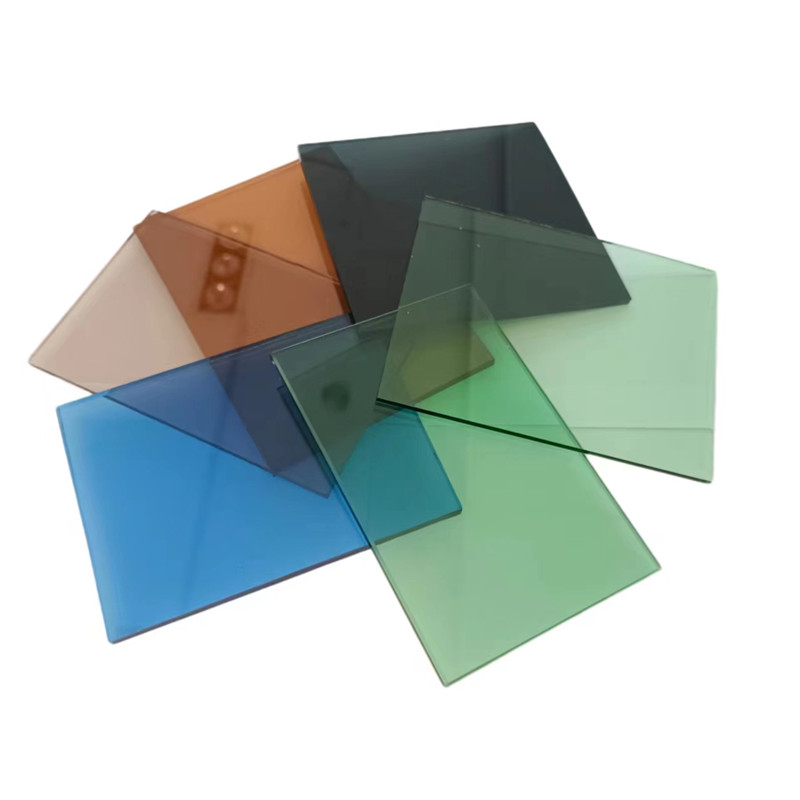

Ordinary glass, bright green, fragile, transparency is not high, easy to aging deformation under rain and exposure to the sun. Float glass, transparent float glass is glass paste through the control gate into the tin tank, due to gravity and its own surface tension floating on the molten tin surface, and then into the cold tank, so that both sides of the glass smooth and uniform, ripples disappear and made. Dark green, smooth surface without ripples, good perspective, with a certain toughness.

Float glass and ordinary glass production process is different, the advantage is that the surface is hard, smooth, smooth, float glass side color is different from the general glass, white, reflective objects are not distorted, and the general deformation of water pattern.

Benefits

Benefits:Smooth and flat surfaces with good transmittance

Flexible size specifications with minimized cutting loss

Substrate for each level of glass processing

Applications

Construction

Mirrors

Furniture and decoration

Optical instruments

Automobiles

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

Top